+86 15633683072

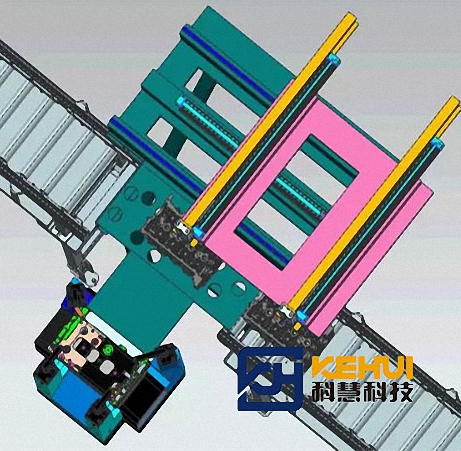

1. High-precision positioning, fast handling and gripping, shortening the tact of the operation and improving the efficiency of the machine.

1. High-precision positioning, fast handling and gripping, shortening the tact of the operation and improving the efficiency of the machine.

2. The robot operation is stable and reliable, effectively reducing non-conforming products and improving product quality.

3. Continuous operation without fatigue, reducing machine idle rate and expand factory capacity.

4. High automation level, improving the precision of single product manufacturing, speeding up mass production efficiency.

5. Highly flexibility, fast and flexible to adapt to new tasks and new products, shorten delivery time.

Technical advantages:

1. Adopting the teaching type programming mode, as long as the manual trajectory is used to go once, the system automatically records the coordinates.

2. The control system adopts DSP and EPGA technology to realize 6-axis linkage and high stability during high-speed operation.

3. The implementation part adopts AC servo motor to achieve high precision, high speed operation and high stability.

4. The transmission part adopts precision ball screw to improve the repeat positioning accuracy and service life.

5. The guide rail adopts high-assembly linear guide rail to improve the repeat positioning accuracy and service life and reduce machine noise.

6. The installation method adopts floor-standing installation, greatly improving the flexibility of the machine.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com