+86 15633683072

1. The core components are imported from Japan, with excellent technical performance:

1. The core components are imported from Japan, with excellent technical performance:

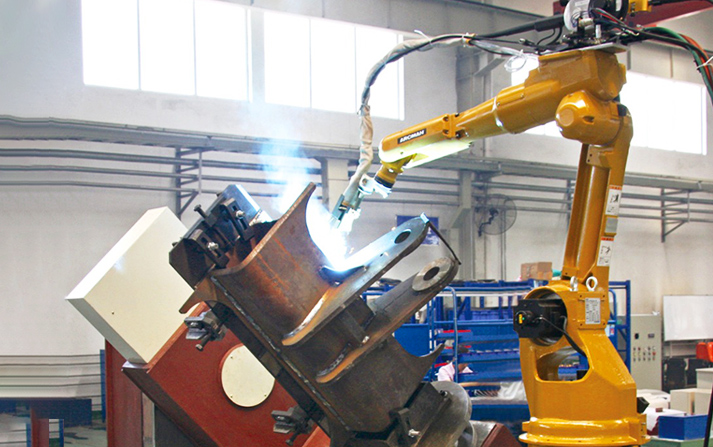

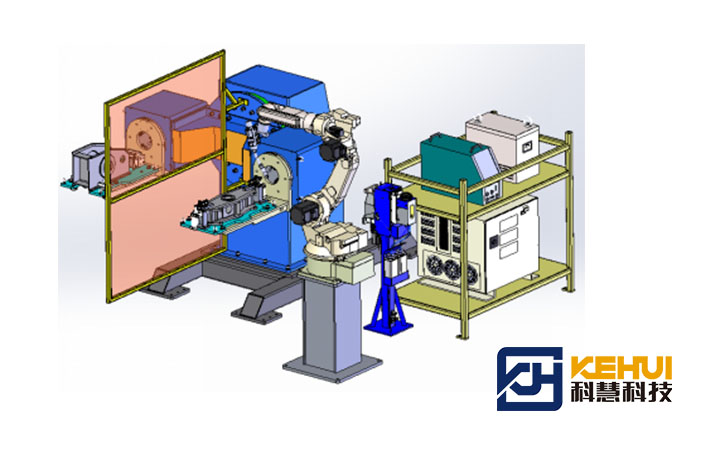

Equipped with Japan Yaskawa welding power supply, low welding spatter welding machine, with pulse welding and short-circuit welding; welding gun with Japan East gold welding torch, excellent performance; welding gun sensing using 360 °anti-collision device to avoid welding collision Damage to the robot body.

2. 360 °all-round welding, taking into account quality and aesthetics:

The three-axis servo flip positioner can be used for 360°free flipping and positioning, and robot for all-round welding. The AC servo motor drives the positioning accurately, the clamping is firm, the starting operation is stable, and the parking position is accurate. Base of the positioner is made from high-quality steel profiles and welded. After annealing, the quality and accuracy are reliable.

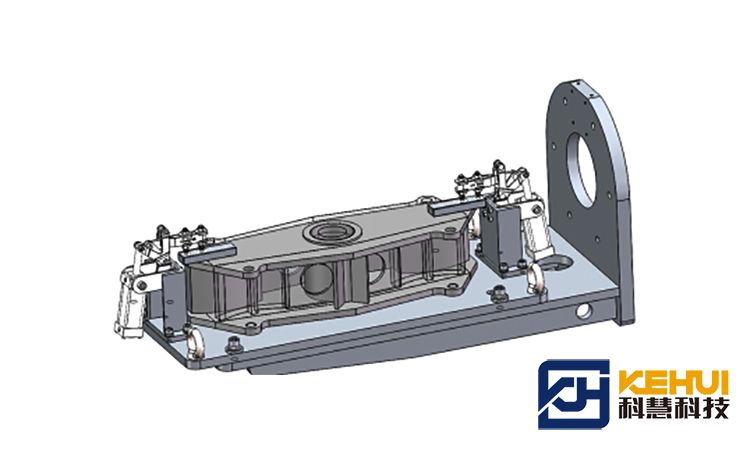

3. The structure is simple and easy to operate, efficient and stable:

The fixtures include three types: balance tooling, front bracket tooling and light front bracket tooling. The tooling fixtures are designed with automatic clamping positioning to enable information interaction with the handling robot. The utility model has the advantages of simple structure, convenient operation, high efficiency of the pair, and firm and stable clamping force.

4. Germany automatic clearing wire cutter, long service life:

The German Binzel clear gun wire cutter TCS is used. The automatic clearing and cutting device consists of a clearing gun station, a wire cutting mechanism and a spray silicone oil unit. The clearing gun station is precise and efficient, the wire cutting mechanism is of good quality, and the spray silicone oil device adopts double nozzle cross jetting, which effectively reduces the number of cleanings and has a long service life.

| Description | MOTOMAN-MA1440 | |

| Mode | YR-MAO1440-A00 | |

| Structure | vertical polyarticular (6 degrees of freedom) | |

| Load | 6kg | |

| Resetting Accuracy *1 | ±0.08mm | |

| Working Range |

S axis (Rotation) | ±170° |

| L axis (Lower arm) | +155°~ -90° | |

| U axis (Upper arm) | +240°~ -175° | |

| R axis (Swing) | ±150° | |

| B axis (Bending) | +90°~-135° | |

| T axis (Twist) | ±210° | |

| Maximum Speed |

S axis (Rotation) | 230°/s |

| L axis (Lower arm) | 200°/s | |

| U axis (Upper arm) | 230°/s | |

| R axis (Swing) | 430°/s | |

| B axis (Bending) | 430°/s | |

| T axis (Twist) | 630°/s | |

| Allowable Moment |

R axis (Swing) | 10.5N·m |

| B axis (Bending) | 10.5N·m | |

| T axis (Twist) | 3.2N·m | |

| Allowable moment of inertia (GD2/4) | R axis (Swing) | 0.28kg·m2 |

| B axis (Bending) | 0.28kg·m2 | |

| T axis (Twist) | 0.06kg·m2 | |

| Body weight | 130kg | |

| Item | Specification |

| Structure | Dust removal structure |

| Size | 600(Width)×520(Depth)×930(Height)mm |

| Gross weight | Below 100kg |

| Cooling method | Indirect water cooling |

| Ambient temperature | Energized: 0~45°C . Storage: -10~60°C |

| Relative humidity | up to 90% (no condensation) |

| Power Specifications | Three-phase AC380V (+10%, -15%) 50HZ (±2%) |

| Grounding | Type D (grounding resistance 100Ω or less dedicated grounding) |

| Input signal | Dedicated signal: input 23, output 5 ;General signal: input 40, output 40; Maximum input signal (option): input 4096, output 4096 |

| Position control mode | Serial encoder |

| Memory capacity | JOB: 200,000 program points, 10,000 robot commands CIO ladder diagram (maximum): 20,000 steps |

| Increase slot | PCI: 2 slots (main CPU) |

| LAN(upper connection) | 1(10BASE-T/100BASE-TX) |

| I/F Number | RS-232C:1 |

| Control method | Servo software |

| Operation unit | AC servo servo package (can be equipped with 9-axis amplifier) |

| Spray paint color | Munsell color series 5Y7/1 |

| Item | Specifications |

| Size | 169(Width)×314.5(Height)×50(Thickness)mm |

| Gross Weight | 0.990kg |

| Material | Reinforced Plastics |

| Machine operation | Selection button, axis operation button (8-axis), value/application button switching mode button (math mode, operation mode, remote mode), emergency stop button, cancel button, small memory card I/F equipment (small memory card is optional) , USB port (1 port) equipment |

| Display Screen | 5.7-inch color LCD, touch screen 640X480 pixels, (Chinese, Japanese, English, other) |

| Protection class | IP65 |

| Cable Length | Standard: 8m, maximum (option): 36m (additional extension cable, option) |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com