Advantages:

1. Double clamping positioning, good positioning effect, no need to locate spot welding, improve welding efficiency.

2. Pulse power supply, closed design of the welding head, good protection effect, uniform and beautiful weld seam.

3. Lightweight structure design, suitable for assembly site with small space.

4.To addresses the issue of operator error in GTAW . computer-controlled process runs with little intervention from the operator.

5.Beautiful welding beam with excellent seal performance. TIG welding, no feeding wire and closed welding space by welding head, together makes high seal performance without new impurity, so its welding beam looks beautiful.

6.Tiny welding head, very convenient to operate in narrow tube installation site.

7.To guarantee high quality repeatable welding. a successful programming monitors variables and performs periodic samples during its test welding. LCD touch screen, easy to input.

Intelligent welding . 100 successful programming stored in PLC, just pick one.

8.High productivity. 2-3 times higher than conventional TIG welding.

9.Easy operation. Clamp device to fix the two separated tubes tightly, no need for spot welding, precise positioning.

10.10 hours continuous welding. qualified welding head and power and water cooling system make it.

11.Portable, freedom of movement.

12.Stable welding. Over 20 years development & improvement based on market

Description:

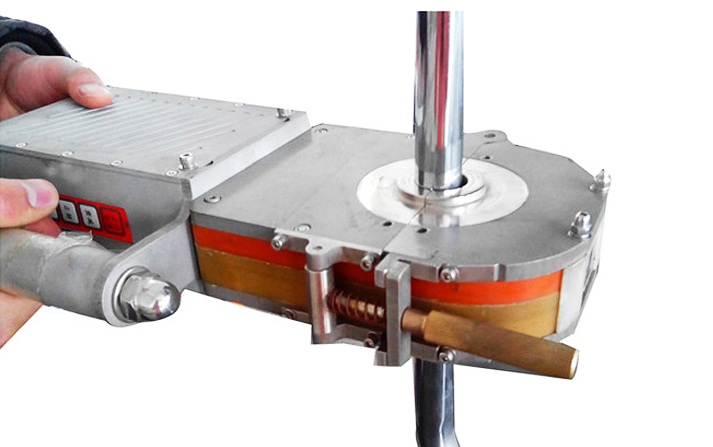

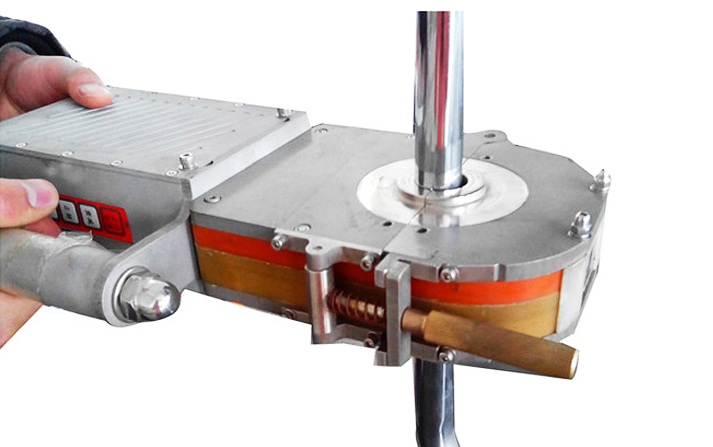

KHGC Closed Head Orbital Welder is a specialized auto arc welding machine whereby the arc is rotated mechanically through 360° around a static work piece of tube to tube with tube specification φ3~φ114 mm and tube thickness 0.8~3mm.

KHGC could address the issue of operator error in gas tungsten arc welding(GTAW).

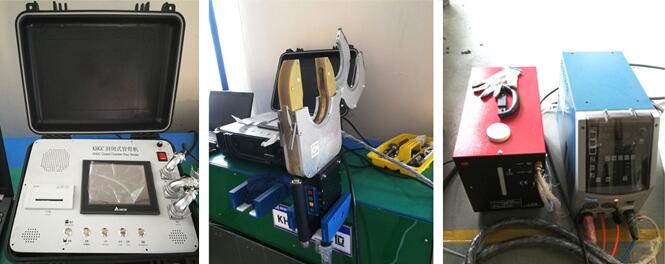

KHGC is composed of power supply, control system,cooling system and welding head.

KHGC could process carbon steel, alloy steel, stainless steel and titanium alloy.

KHGC is capable of making welding beam with high seal performance and clean outlook.

KHGC is designed with tiny welding head, very convenient to operate in narrow tube installation site.

Therefore, KHGC orbital welder is widely adopted in the installation of plants such as food& alcohol plant,chemical industry, medicine and other industries.

Other types:

Welding Product:

Certifications