+86 15633683072

| Primary source | Three-phase AC 380±10% |

| Rated power | 50kVA |

| 2nd max. short circuiting current | 15000A(5% loading ratio) |

| Max. electrode pressure | 3000N |

| Jaw depth of welding tongs | 350mm |

| Electrode stroke of welding tongs | 120mm |

| Max. dimension of weldable pieces | 750*650mm |

| Height of working space | 850mm |

| Pressure of cooling water | 0.20~0.30Mpa |

| Flow of cooling water | 20~30L/min |

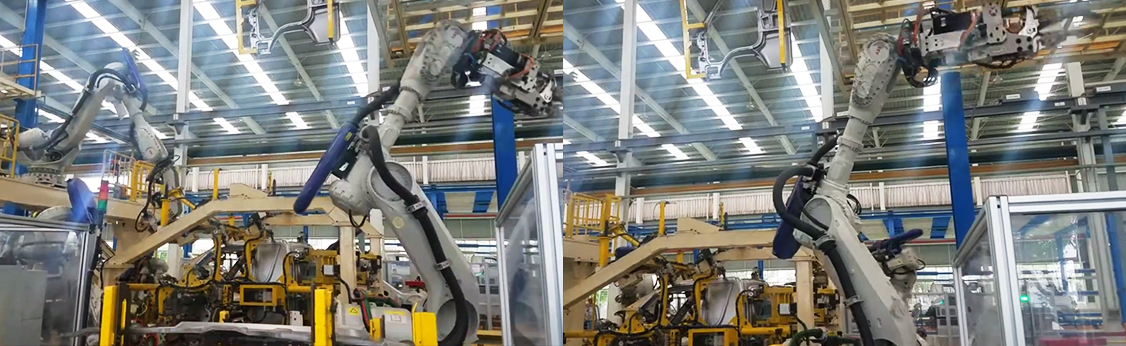

| Robot system(KUKA) | KR150-2 |

| Pneumatic system pressure (MPa) | 0.6 |

| System dimension(L*W*H) | 6000×5000×2200 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com