+86 15633683072

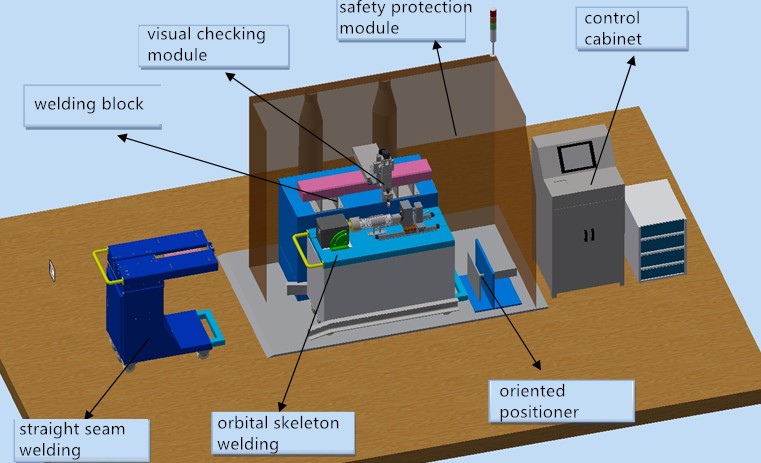

1. Imported power supply equipment and customized control system:

1. Imported power supply equipment and customized control system:

The IGBT inverter is used to control the DC pulse power supply, and it is integrated with our company's control system through various process means to make the control welding parameters convenient, effective and easy to understand. The welding speed can be 0.1~10r/min. The stepless adjustment is greatly reduced, which greatly reduces the requirements for the professional welding quality of workers.

2. Professional wire feeding mechanism, auxiliary to complete high process requirements:

The wire feeding mechanism adopts Shenchuang 42 stepping motor and PX40 12:1 precision reducer. With the professional SB-10C/D wire feeder, the wire diameter can reach 0.8~1.6mm, and the maximum wire feeding speed can reach 2.5m. /min. The wire feeding mechanism of the wire feeding mechanism is precise and reliable, and can be precisely matched with the Sansha IA2001TPH welding machine to complete the complicated argon arc welding process.

3. Complete welding torch walking mechanism and expansion of welding flexibility:

3. Complete welding torch walking mechanism and expansion of welding flexibility:

It includes X-axis left and right running mechanism, Y-axis front and rear running mechanism, manual up-and-down adjustment mechanism, manual rotary table and Z-axis arc protection mechanism. The walking speed of the X-axis left and right running mechanism is 0~100mm/s, the speed of the Y-axis running back and forth is 0~100mm/s, and the Z-axis arc-raising protection mechanism is 0~50mm/s.

4. Equipped with international high-quality visual tracking system:

Equipped with Japanese Keyence vision sensor and image processing system to realize the automatic detection and positioning of the plug welding hole; in the sub-project, if you want to ensure that the center of the circle is found to be reliable, make sure that the lining ring will need to completely block the hole in order to stably obtain the characteristics of the hole that requires plug welding.

5. Welding protection device:

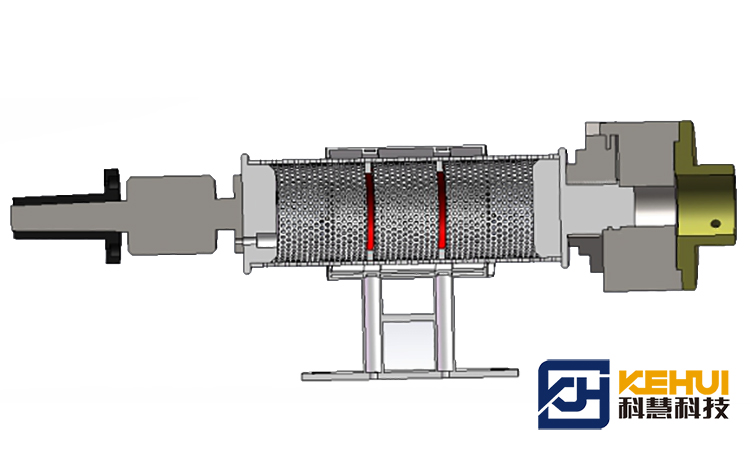

During the welding process, the protective gas is passed through the hollow main shaft into the internal process of the workpiece to be welded, and the inside of the workpiece is protected from oxidation.

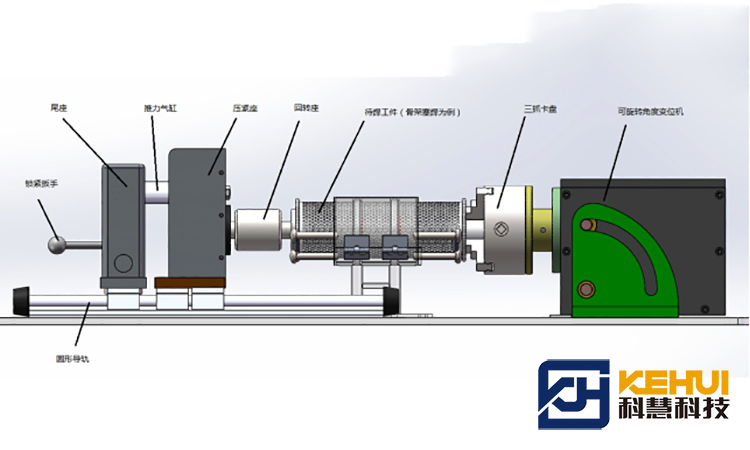

a) Before the welding starts, the height of the welding torch is adjusted by the manual up-and-down adjustment mechanism. The angle of the welding torch is precisely rotated by the manual, so that the height of the welding torch and the angle of the relative welding seam are in the proper position. When the welding starts, the welding torch is automatically driven by the XYZ axis. Send to the appropriate arcing position.

a) Before the welding starts, the height of the welding torch is adjusted by the manual up-and-down adjustment mechanism. The angle of the welding torch is precisely rotated by the manual, so that the height of the welding torch and the angle of the relative welding seam are in the proper position. When the welding starts, the welding torch is automatically driven by the XYZ axis. Send to the appropriate arcing position.| No. | Item | Parameter | Unit |

| 1 | Skeleton wall thickness range | 0.5~3 | mm |

| 2 | Welding range of small hole plug | Dia≥2,depth≤3 | mm |

| 3 | Welable skeleton range | Diaφ20~80,length≤300 | mm |

| 4 | Stainless steel welding wire dia | 0.8~1.6 | mm |

| 5 | Wire dia. | 0.8~1.6 | mm |

| 6 | Max. wire feeding speed | 2.5 | m/min |

| 7 | Skeleton welding frontal high | ≤1 | mm |

| 8 | Skeleton welding back high | ≤0.5 | mm |

| 9 | Weld seam gap at both sides | ≤2 | mm |

| 10 | Plug welding frontal height | ≤1 | mm |

| 11 | Plug welding back height | ≤0.5 | mm |

| 12 | Suitable piece material | Stainless steel | |

| 13 | Axis X walking speed | 0~100 | mm/s |

| 14 | Axis Y walking speed | 0~100 | mm/s |

| 15 | Axis Z arc protection mechanism | 0~50 | mm/s |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com